Solutions

Automotive Coatings

Nippon Paint Automotive Coatings (NPAC) is a leading global paint manufacturer that handles all automotive coatings in-house. From Electrodeposition Paint (E-coat), Primer, and Basecoat/Clearcoat for the auto body, to paint for plastic bumpers and interior parts. Drawing on our understanding of the overall process of automotive painting and our wealth of coating expertise, we realise a system that maximises the properties of each coat and paint film, while together creating synergy.

The automotive industry has a significant growth potential, mainly in emerging countries. Our group has been accelerating business deployment in the overseas markets that continue to expand. As technological innovation toward CASE is underway, we offer high-quality and highly functional products as a professional manufacturer. We aim to become the leading company in the automotive coating field by fully demonstrating our group synergies.

Our Processes

Waterborne primer is applied in OEM coatings on the E-coat and before the Basecoat and the Clearcoat. The function of the Primer is to prepare the E-coat surface for the top coat. Basic requirements of the Primer are to cover the structure of substrate and the layering below, give protection against UV light to the E-coat. Beside this, the mechanical properties are of high interest to protect any structural damage of the E-coat.

To achieve good appearance the primer has been sanded prior to application.

As the primer impacts the colour location of the top coat, the Primer shades dark grey (anthracite), middle grey and old white are available. Typical Primer are applied with a coating thickness of 35-40 µm and cured at temperatures of 165°C to achieve final crosslinking density to fulfill the OEM needs.

Trend-based Solutions

Based on the latest OEM trends to decrease VOC level of the paints in general and energy consumption during the curing process, reformulation of the resin design has been carried out to achieve a more environmentally-friendly Primer that give comparable properties. A new Primer generation called Thin Film Primer has been developed and can achieve the full spectra of properties with a film thickness of only 20-25 µm. That means, that mechanical and UV protection are given at a significantly reduced film thickness without impacting film leveling.

A new solution has also emerged, the Primerless Basecoat system, which is becoming the new standard for auto OEM paint.

The purpose is to replace the Primer and Basecoat by one layer with the same final performance, yet reducing the VOC content and the paint process cost.

Our Contribution to the

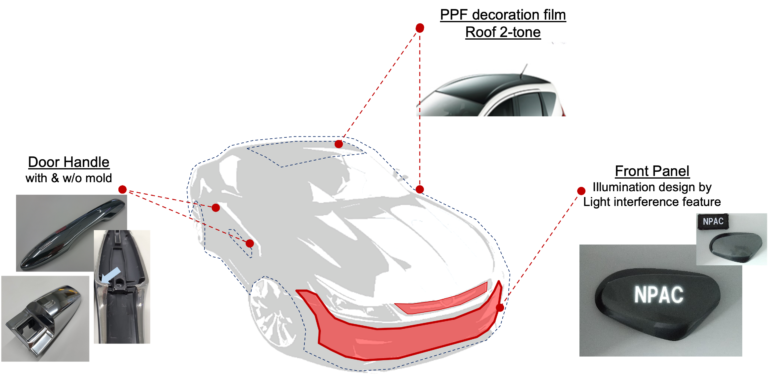

Decorative Film Market

Our unique high stretching film technology is interior and exterior compatible and can bring extra-features in terms of designs, sustainability & CN considerations.

For injected parts protection & decoration, compared to paint technology & existing films, NPAC films have superiority in all important factors in Design such as 3D complex shapes decoration, reliable color matching with body.

Automotive Refinish

Automotive refinish paints that fully demonstrate synergies with automotive coating technologies

We apply cutting-edge technologies, which have been refined through more than 50 years of operations in the field of coatings for new cars as a general paint manufacturer, to the repair field. We have developed paint products and coating technologies suitable for repair. We have always pursued repair products that ensure both high finishing quality, which satisfies professional painters, and on-site workability, and we have conducted research and development on coating technologies suitable for automotive repair.

Vision Behind the Three E’s for People and the Environment

Our automotive repair paint brand “nax,” which has recently been deployed globally, offers a coating system that reduces the environmental impact and increases efficiency of the repair work based on the concept of EASY × EXCITING × ECOLOGY = e3 (E-cube). EASY: aiming to improve workability and the color toning quality and reduce the coating time EXCITING: aiming to attain high hiding power and finish quality by introducing the latest technologies ECOLOGY: aiming to improve the environment by cutting the VOC emissions