E-coat

What is E-coat?

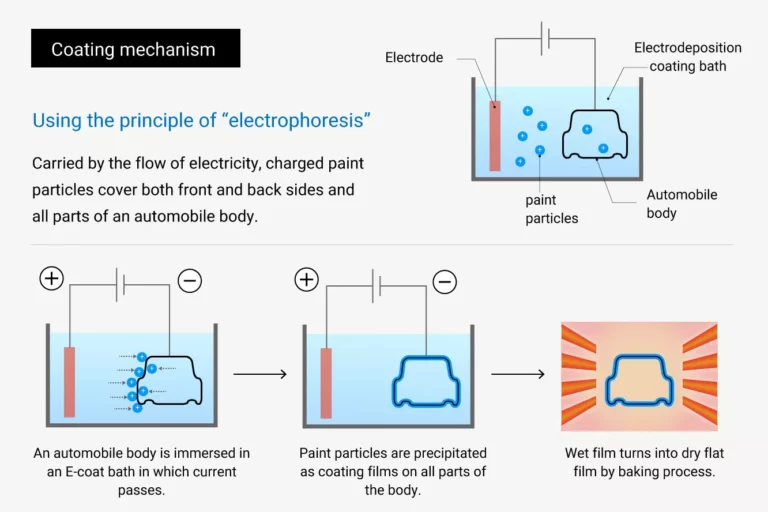

Electrodeposition coating technology, or E-coat, refers to a unique coating system in which an entire auto body is immersed in a large paint-coating bath. A coating film that ensures rust prevention performance is formed both on the outer surface and the complicated internal structures of the car body.

An automotive coating film, which is 0.1 mm thick, consists of many layers. It has various functions, such as design performance for beautiful appearance, weather resistance performance, anti-chipping performance, and rust prevention performance. E-coat forms an undercoating film, whose thickness is only one-fifth of that of a human hair, to protect automobiles from rust.

E-coat Process

E-coat (Electro Deposition Coating) is an undercoat for Auto OEM with the purpose of anti-corrosion protection and appearance improvement.

The application method is pretty unique as based on dipping the complete car body in an E-coat bath followed by an electrolysis reaction:

The E-coat bath contains cationic particles which by electrophoresis attach to substrate. Due to this process, compared with other paint system, the paint loss is very low with a paint efficiency of 90-95%.

After deposition and curing at 160°c a solid film is generated by the crosslinking of the polymer.

Benefits of NPAC's E-coat

- Low paint usage ~5%

- C02 emission decreased by 19% vs. normal process

- Eco-friendly – tin-free technology

- Brand new low temperature curing for EV and CO2 reduction

Future E-coat Technology

To decrease CO2 emission at customer paint shop, NPAC has developed a new and unique low baking E-coat technology…

…allowing us to reduce the curing temperature to 130°c.

✔ Improving rust prevention durability

✔ Eliminating environmental pollutants during recycling and scrapping

✔ Reducing CO2 emissions from automotive factories