Plastic Coatings

Fully Integrated

Today, automotive plastic parts are fully integrated for each new OEM project.

As a consequence, more than 30% of a vehicle’s weight now consists of plastics substrates, whether for exterior or interior parts.

NPAC Europe is a major player in the painting of these plastic parts, with specific ranges dedicated to it.

Our Process

Most common plastics substrates are Polypropylene and ABS, respectively for bumpers and mirrors, but also SMC for automotive tailgates and truck parts. Then, the paint technology has to fit to these different substrates.

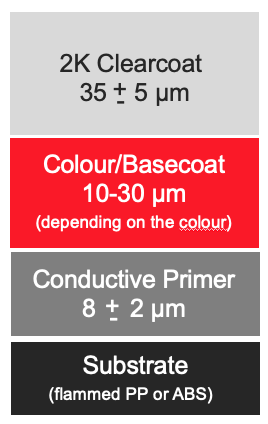

Of course, several paint layers are mandatory for exterior parts, to suit our customer requirements.

The first layer, the conductive Primer is probably the most important because of its specific formulation that allows good adhesion on substrate and electrostatic application.

The second layer, the Basecoat, is mandatory to reach the color matching with body and good colour harmony.

In case of waterborne Basecoat, NPAC has developed a primerless technology that comprise adhesion promoter binder system to ensure perfect direct adhesion of the BC to the substrate and in which the necessary conductivity is brought by the water composition of the BC. Such paint replace the 2 layers of primer/BC combining their properties in 1 unique BC layer.

Finally, Clearcoat, with only one baking at 80°C due to plastic heat sensitivity, will globally protect plastic parts with very high gloss.

Despite the difference of paint technology used on plastic and steel, the final appearance and coloron plastic parts match exactly to the car’s body.